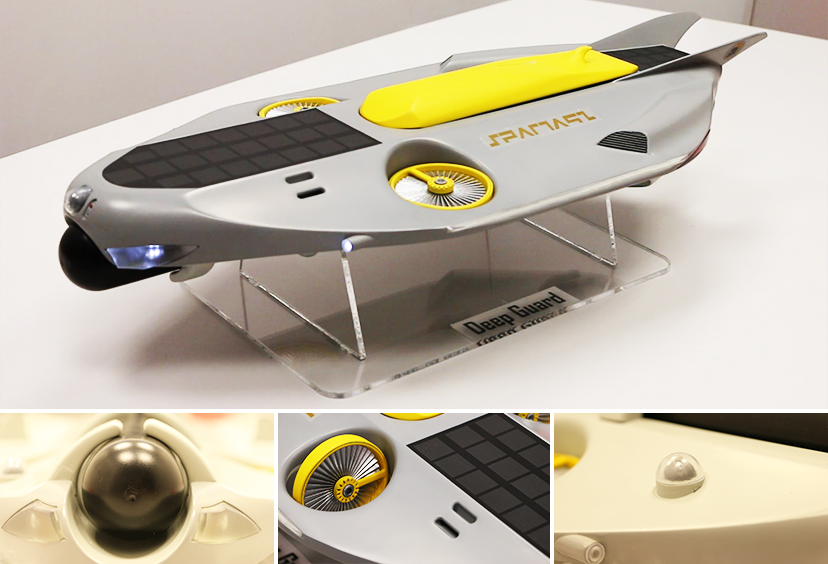

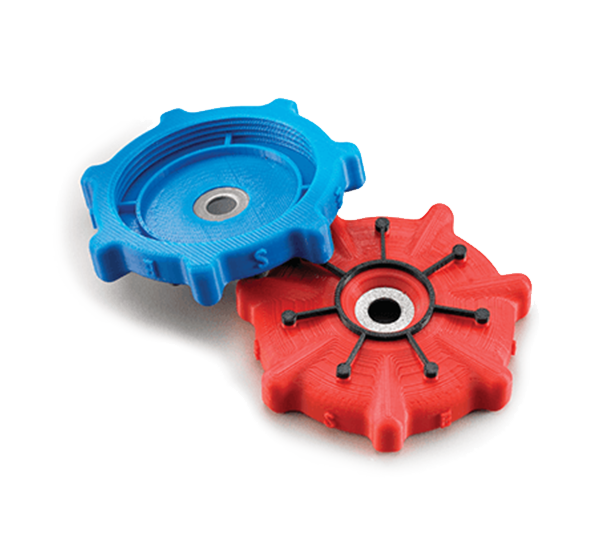

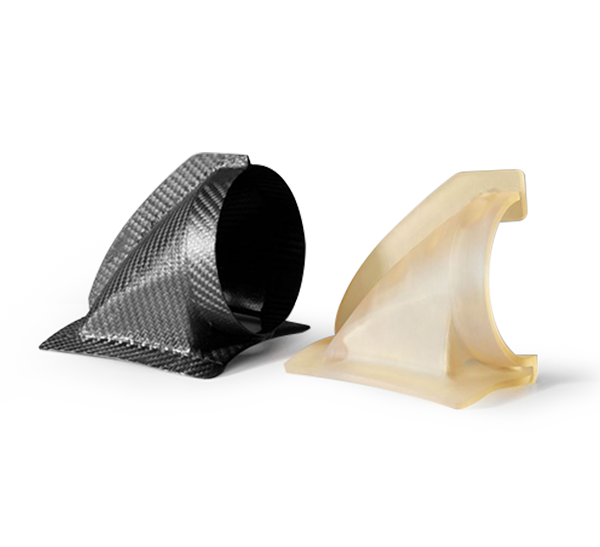

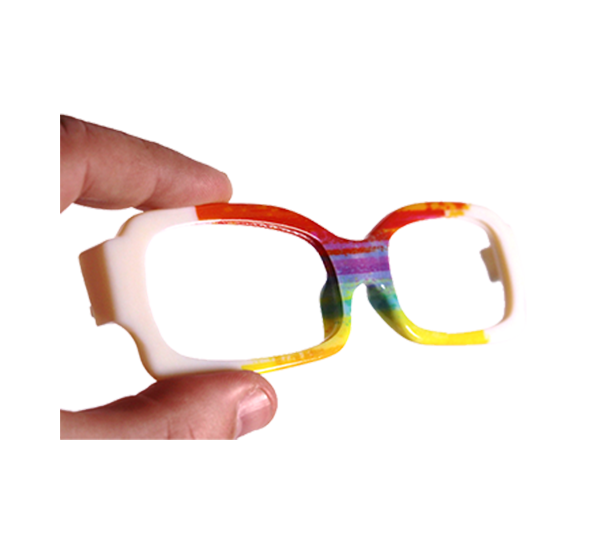

How to order a 3D printed parts?

- Contact us via contact form or e-mail.

- Send to us your CAD files. We will help you to choose right technology and materials according to aplication.

- Accept 3D printing offer and wait for 3D print. We will print, postprocessed your part and send it yo your address.

show less

show less